No products in the basket.

PPE, Safety Gloves

EN 388:2016 Protection Against Mechanical Risks

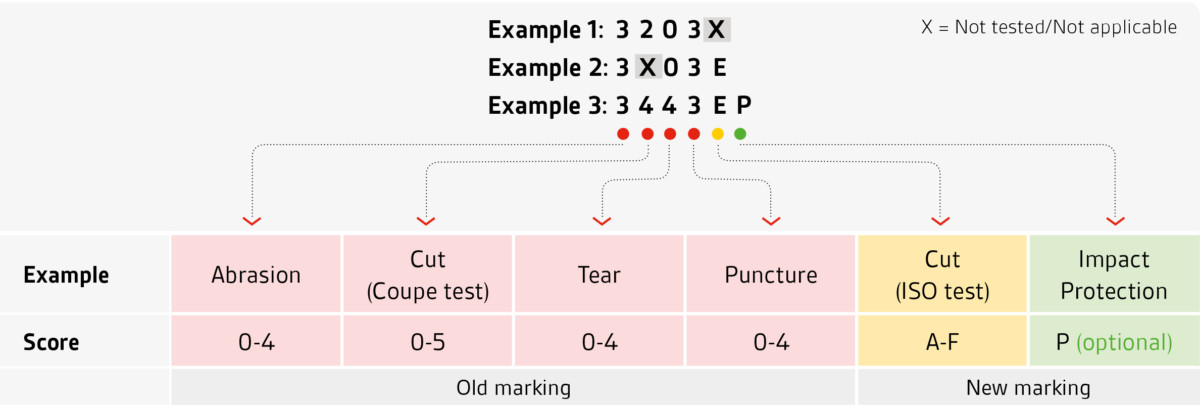

The European Standard, EN 388 covers the test requirements for safety gloves that offer protection against mechanical risks. The standard uses index values to rate the performance level of the glove in protecting the user against the dangers from abrasion, blade cut, tearing, puncture and impact.

Understanding the various glove markings and the difference between EN388:2003 and EN388:2016 standards however can become a little confusing, which is why we’ve put together the following guide to help explain the relevant safety tests and ratings.

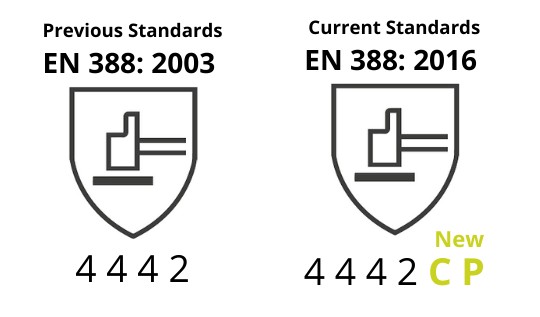

In 2016 the previous standard EN388:2003 was updated with changes to the way gloves are tested for Cut Resistance. Other differences between EN388:2003 and EN388:2016 include changes to Abrasion Resistance testing and an optional Impact Protection test, however the main difference from the previous standard is the test method and performance levels for Cut Resistance.

Let’s start with the numbers on the back of the glove. The current standard EN388:2016 has kept the first 4 numbers in the same format but in addition there are 2 new letters as shown below:

Abrasion Resistance Test

The abrasion resistance test is carried out through the Martindale Abrasion Machine. A sample of the material is cut from the palm of the glove and fitted to a rubbing head of fixed size and weight. This is then moved in an elliptical motion over a table covered with abrasion paper. EN 388:2016 uses a new type of abrasive paper. Due to this change, some abrasion levels of protective gloves may change when tested to the updated standard.

Performance levels range from 1 to 4 and are as follows:

1 – abrasion resistance of cycles between 100 – 500

2 – abrasion resistance of cycles between 500 – 2,000

3 – abrasion resistance of cycles between 2000 – 8000

4 – abrasion resistance of cycles over 8000

Cut Resistance (Coupe Test Method)

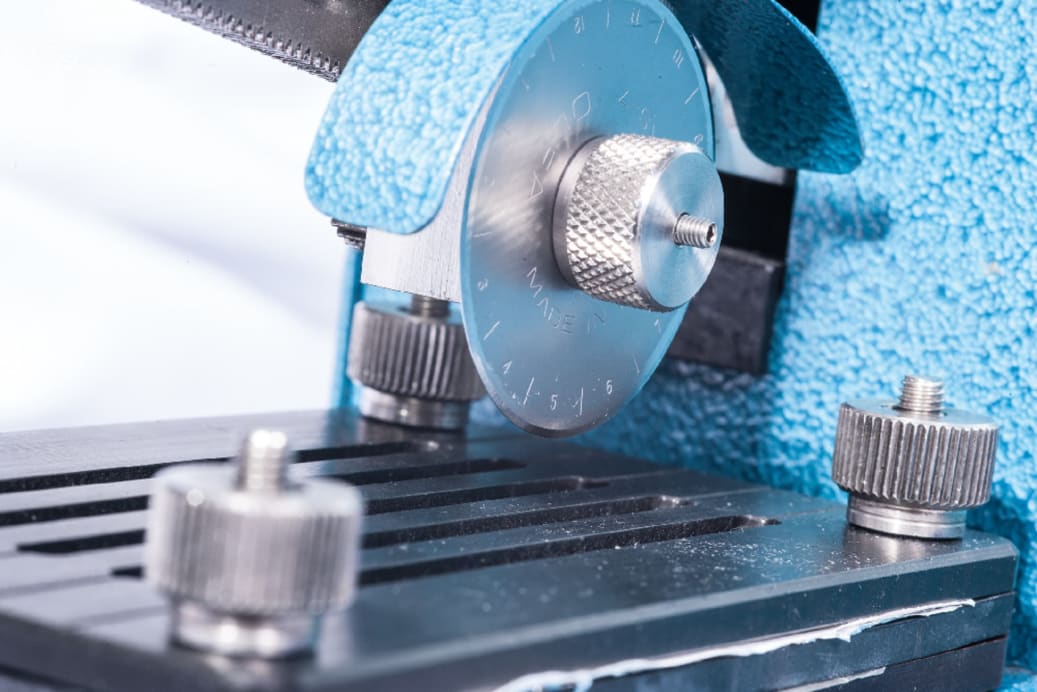

For EN388:2003 the ‘Coupe Blade Cut Test’ was the standard test method for assessing cut protection. A rotating circular blade moves horizontally to-and-fro across a fabric sample with a fixed force of 5 Newtons (N) applied from above the sample.

The test ends when the blade breaks through the sample material and the result specified as an index value. This result is determined by the cycle count needed to cut through the sample and additionally by calculating the degree of wear and tear on the blade. This represents an exposure type cut risk in the workplace.

Performance levels range from 1 to 5 and are as follows:

1 – cut index of 1.2 – 2.5

2 – cut index of 2.5 – 5

3 – cut index of 5 – 10

4 – cut index of 10 – 20

5 – cut index of over 20

The ‘Coupe Test’ is prone to inaccuracies when used to test higher cut-resistant materials because these materials can cause the blade to become blunt during the test, giving a better score for the glove than when a sharp new blade was used.

Many workplace risk assessments were identifying a minimum level of Cut 5 protection was required but with a wide range of gloves all achieving Cut 5 under the Coupe test it was time to refine the test method and improve the accuracy of the results. A new Cut test was needed for these higher cut-protection level gloves and this is known as the EN ISO 13997 test, or the ‘ISO test’ for short.

New: EN ISO 13997 Cut Test

For safety gloves that have been created with materials designed to have a blunting effect on blades, additional cut protection tests must now be carried out.

Any sample fabric testing for cut resistance using the ‘Coupe Blade Cut Test’ as described above, which blunts the blade during the test, will be marked with an X and then further tested using the new EN ISO 13997 test. A brand-new blade must be fitted for every test performed.

This is to ensure the degree of protection provided by the glove is as accurate as possible. The objective of this new cut test is to determine the resistance of the safety glove by applying greater force in a single movement to the fabric sample. A sharp-edged blade is dragged over the material once, allowing an accurate calculation of the minimum force required to cut the sample material in a 20mm blade stroke. This produces a more accurate representation of the type of cut risk that can be experienced in the workplace.

Performance levels are measured in Newtons and range from A to F as follows:

EN ISO cut resistance A – 2N to 5N

EN ISO cut resistance B – 5N to 10N

EN ISO cut resistance C – 10N to 15N

EN ISO cut resistance D – 15N to 22N

EN ISO cut resistance E – 22N – 30N

EN ISO cut resistance F- above 30N

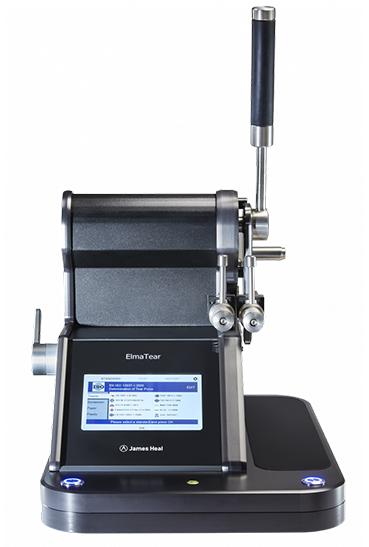

Tear Resistance Test

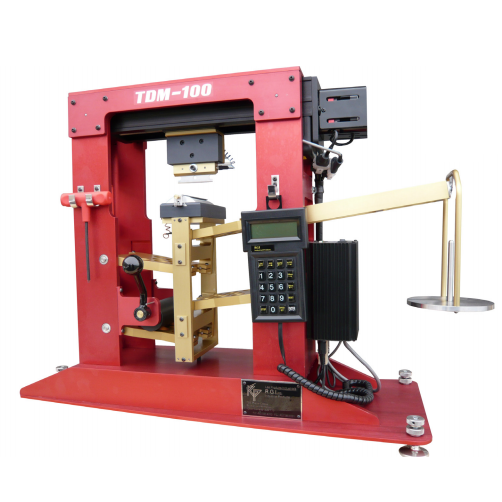

In the tear resistance test, four samples from the palm of the glove are clamped in a standard tensile strength testing machine. The jaws move apart at a speed of 100mm per minute and from this the force required to tear the sample is measured in Newtons.

Performance levels range from 1 to 4 and are as follows:

1 – tear resistance of peak force between 10N and 25N

2 – tear resistance of peak force between 25N and 50N

3 – tear resistance of peak force between 50N and 70N

4 – tear resistance of peak force is at least 70N

For single materials, the level is decided by the lowest result of the four tests. For multiple, unbonded layers, each layer must be tested individually and the level is based on the lowest individual result of the most tear resistant material.

Puncture Resistance Test

The puncture resistance test consists of a compression test machine which pushes a rounded stylus 50mm (the size of a standard roofing nail) into the sample cut from the palm of the glove at a speed of 100mm per minute. From this, the maximum resistance force is recorded, with levels decided by the lowest of the 4 test results.

Performance levels range from 1 to 4 and are as follows:

1 – puncture resistance force of between 20N and 60N

2 – puncture resistance force of between 60N and 100N

3 – puncture resistance force of between 100N and 150N

4 – puncture resistance of at least 150N

Impact Resistance Test

This impact test for EN388:2016 is performed according to the EN 13594 standard.

To claim impact protection, or ‘P’ rating, a glove must reduce the effect of impact on the hand when tested over the fabric area of the four connected knuckle joints (metacarpo-phalangeal joints).

The test requirement is 2.5kg striker (flat face 80 mm diameter) generating a 5 Joules energy when striking the glove. This must not transmit a force that exceeds 7kN. If the glove meets the required impact protection level, the letter P will appear in the last position (6th value) to the series of EN388:2016 performance levels.

Hopefully, this will have simplified the varying markings that are displayed but if you’re still confused don’t leave it to chance. Please contact a member of our Technical Team who will be available to advise you on the wide range of gloves we have on offer. For further information please call 0800 161 3661 or email [email protected].

Clad Safety has been operating for over 30 years and takes pride in the excellent service that we offer to our customers. Our product range, combined with expert technical knowledge allows us to offer valuable workwear and PPE solutions to a wide range of business.