No products in the basket.

Sustainability, Sustainable Workwear, Workwear

Recycled Polyester – Hero or Villain, you Decide!

We buy more clothes per person in the UK than any other country in Europe (according to a recent study by Greenpeace, Nov 2020). The knock-on effect of our increasing consumerism results in around 300,000 tonnes of textiles being either burned or buried in landfill each year. It seems impossible that the UK alone could be responsible for such a colossal figure but as we start to take a wider view around the globe it becomes clear that there is a much larger underlying problem than just excessive buying.

Nearly half of the world’s clothing is made of polyester, or polyethylene terephthalate (PET) the most common type of plastic in the world. Given the increasing trend for more stretchy, resistant garments the use of polyester is set to multiply over the next few years. The overriding issue however is that polyester takes approximately 200 years to decompose. So where does that leave the buyers of workwear and PPE and where does it leave the manufacturers who rely so heavily on it for their products?

The answer, or not depending on your point of view, is recycled polyester (rPET), a term used to describe polyester that is made from either discarded textiles or plastic waste (water bottles). According to a recent McKinsey and Company poll, 67% of all consumers consider sustainable materials an important factor when buying clothing so naturally, companies have been eager to respond. Fashion houses have pledged to replace virgin polyester with recycled polyester, whilst workwear and PPE suppliers have added lines of sustainable workwear to assist businesses in meeting their net zero objectives. Sounds like the perfect solution – but is it?

Unfortunately the technology for textile-to-textile recycling of polyester is still very much in its infancy with only 1% of all recycled polyester currently being produced this way. The greater majority of rPET in today’s marketplace therefore is derived from plastic that has been ‘downcycled’ from other plastic.

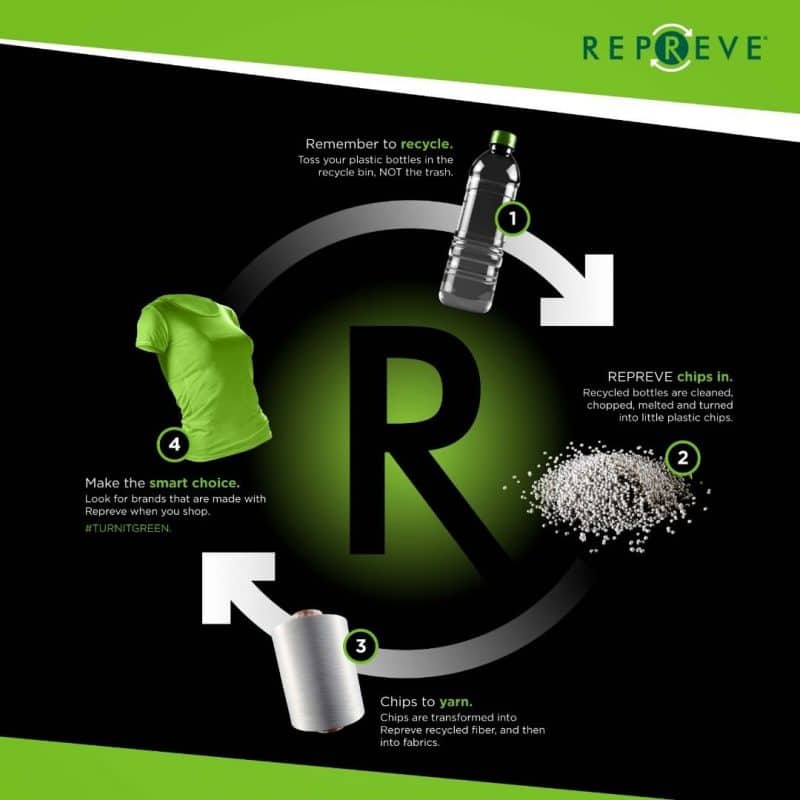

This process of mechanical recycling involves taking discarded plastic bottles from out of the supply chain, melting the plastic down and re-spinning it into polyester fibre for garments. The only disadvantage with this process is that whereas plastic can be recycled into plastic multiple times, plastic can only be recycled into polyester fibre for garments once. Eventually, the discarded garments will ultimately end up in landfill. According to fashion designer Stella McCartney, widely recognised for her outspoken views on sustainable clothing, if nothing changes by 2050 clothing waste will take up a quarter of the world’s carbon footprint.

So what are the pros of using recycled polyester?

Recycled polyester undoubtedly gives a second life to material that is not biodegradable and would otherwise end up in landfill, or the ocean. In addition to the clothing we send to landfill the UK also sends a further 5 million tonnes of plastic waste to sites on an annual basis. According to the NGO Ocean Conservancy, globally an extra 8 million metric tonnes of plastic enters the ocean each year too – that’s on top of the estimated 150 million tonnes of plastic that’s already floating around out there. If we keep this pace up there will be more plastic floating around in our marine environments than fish.

Recycled polyester is almost as good in terms of quality as virgin polyester but its production takes 59% less energy according to a 2017 study by the Swiss Federal Office for the Environment. In fact UK sustainability charity, WRAP estimates that producing rPET reduces carbon emissions by 32 per cent, which is a significant figure globally given the potential quantities involved.

By using recycled polyester we are also reducing the amount of raw materials such as natural gas and crude oil that need to be extracted from the Earth to produce the virgin product. Given the staggering volume of plastic already in circulation re-utilising it makes perfect sense. Rightly or wrongly plastic is already in our supply chain so if we can reduce the amounts discarded, maintain the earth’s raw materials, prolong the life of landfill and reduce toxic emissions from incinerators, why would we not?

What about the cons?

There is an academic debate regarding the calculation of CO2 emissions when comparing the production of virgin polyester with recycled polyester as the ‘impact of the fibre’s first life is not included in the overall environmental assessment of recycled fibres. If it was, results would differ’ according to a report from the Swiss Federal Office for the Environment.

Recycling plastic has its share of issues too. Studies have shown that plastic bottles leach antimony, a substance linked with cancer. Antimony oxide is typically used in the process of making both plastic bottles and polyester however health agencies around the world say there is ‘no reason for concern as the quantities are too small to cause alarm’ (500mg/kg of PET). Despite this, finding substitutions for the use of antimony is still recognised as being one of rPET’s challenges for the future.

The process of mechanical recycling; taking a plastic bottle, washing it, shredding it, turning it back into a polyester chip and then taking this through the traditional fibre making process can also have its share of problems. The chips generated through mechanical recycling vary in colour making colour consistency difficult for manufacturers to achieve. Chlorine-based bleaches are often used to whiten the base colour before dyes are then added. The resulting inconsistency of dye uptake can make it hard to maintain batch-to-batch colour consistency leading to increased levels of re-dyeing to get the perfect match – all of which requires additional water supplies, chemicals and energy.

Recycled polyester is also known to release microplastics, microscopic plastic fibres that enter our water system through the process of washing. According to a study conducted by Plymouth University, each cycle of a washing machine can release more than 700,000 plastic fibres into the environment. Regardless of whether the polyester is virgin or recycled polyester it is accepted that both man-made fabrics contribute to microplastics pollution.

The Conclusions?

The question of whether we should be wearing polyester at all is obviously one that cannot be ignored. However you weigh up the pro’s and con’s, neither polyester nor recycled polyester is a natural fibre, both require environmentally unfriendly processes to be produced, both leach microplastics into the water system through washing and neither are biodegradable. That said, the properties of both fabrics make them particularly suitable for a vast range of fashion, athleisure clothing, uniforms, workwear and PPE items so without a comparable alternative, like it or not, they’re here to stay.

With so much plastic already in the system, it seems more logical (and given the significant global challenges, critical) to utilise this and increase production of rPET than continue producing virgin polyester. Finding a cost-effective circular or ‘closed loop’ solution for recycling therefore is key. Research into chemical and more importantly textile-to-textile recycling activities is underway however both have their issues and still remain more expensive than the mechanical processes currently used.

Textile Exchange and the United Nations Framework Convention on Climate Change’s Fashion Industry Charter for Climate Action are launching a joint initiative to further spur a shift in the market towards the uptake of recycled polyester. The 2025 Recycled Polyester Challenge aims to bring the percentage of recycled polyester in the marketplace up from 14% to 45% by 2025. The charter aims to encourage brands to commit to the most ambitious uptake target possible with an aim to reach an absolute 90% recycled volume share by 2030.

Whether you agree with the use of recycled polyester or not it’s here for the foreseeable future and there will undoubtedly be a greater emphasis placed on buying more sustainable workwear solutions in the years to come.

If you would like to find out more about the sustainable clothing ranges Clad Safety have on offer, please click here.

Clad Safety have been operating for over 30 years and we take pride in the excellent service that we offer to our customers. Our product range, combined with expert technical advice allows us to offer valuable workwear solutions. For further information or to find out more on how Clad Safety can support your PPE needs please contact our Customer Service Team on 0800 161 3661 or email [email protected].

Any opinions expressed in this article are those of the author.