No products in the basket.

PPE, Safety Gloves

What Are The Safety Standards For Thermal Safety Gloves?

Did you know there are a number of safety standards for thermal safety gloves? We have previously discussed EN 388:2016 which covers Protection Against Mechanical Risks but now we are going to explore EN 511:2006 Protecting Against Cold and EN 407:2004 Protecting Against Thermal Risks. There are many hazards in the workplace which require thermal protection including exposure to cold environments, heat and flame.

Understanding the various glove markings and the difference between EN 511:2006 and EN 407:2004 standards however can become a little confusing, which is why we’ve put together the following guide to help explain the relevant safety tests and ratings.

EN 511:2006 Protecting Against Cold

The EN 511 symbol displays how much protection a glove will provide against risks from cold.

Alongside the symbol, there will be three numbers as shown in the table below:

|

DIGIT |

TEST |

MARKING ON GLOVE |

|

A |

Resistance to convective cold (0-4) |

4 |

|

B |

Resistance to contact cold (0-4) |

3 |

|

C |

Water penetration after 30 mins (1 = pass, 0 = fail) |

1 |

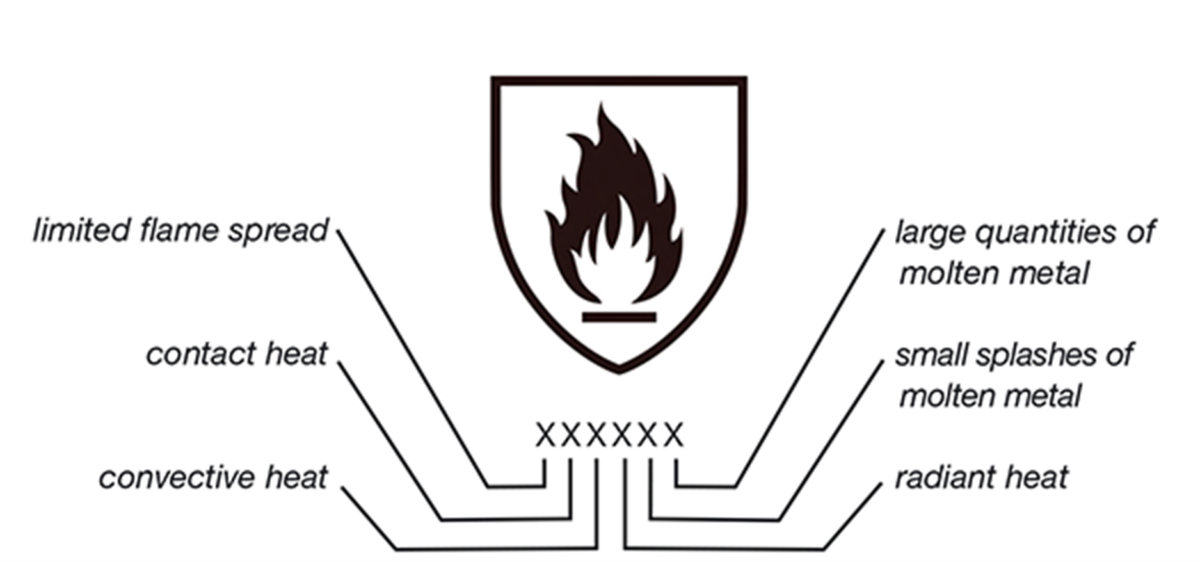

EN 407:2004 Protecting Against Thermal Risks

The EN 407 standard measures a glove’s thermal resistance against six different tests.

Limited flame spread test (Test method EN ISO 15025:2016 Method A)

The limited flame spread test is used to assess the ability to protect the wearer’s hand if it comes into close proximity with a naked flame. To give good results in this test, the gloves do not need to be inflammable but they must inhibit combustion and burn slowly enough for the wearer to recognise this and safely remove the gloves.

Contact Heat (Test Method EN ISO 12127-1:2015)

Through conduction, heat is transferred within and through physical bodies. During use, the wearer of the gloves will intend to hold a hot item and the heat may transfer through the gloves and into the wearer’s hand. Gloves with this type of contact heat protection would also be able to protect from any accidental contact, such as the back of the hand touching the internal sides of an oven.

Convective Heat (Test Method EN ISO 9151:2016)

‘Convection’ is the mechanism of transfer of heat from the source to another place by the movement of fluids such as water or air. Heat transmission through gloves is largely determined by its thickness, including any air gaps trapped between the adjacent layers.

Radiant Heat (Test Method EN ISO 6942:2002)

Heat will transfer between physical bodies which may be separated spatially through thermal radiation in the form of electromagnetic waves in the infrared spectrum in all directions from the hot body. The intensity of the radiation (characterised by the ‘heat flux density’ – the flow of energy per unit area per unit of time, expressed in the SI system as W/m²) will influence the degree of transfer that occurs. It also depends on the distance from the object according to an inverse square law. Radiant heat from hot bodies can be very intense and is invisible. It can result in injury or even spontaneous ignition long before any conductive contact is made with the source. A dramatic example is how the Sun’s rays can be concentrated through a magnifying glass to ignite paper. The results are shown in the table below on a scale of 1 to 4; 1 being the lowest, 4 the highest.

|

DIGIT |

TEST |

RESULTS MEASURED IN: |

RESULTS |

|

1 2 3 4 |

|||

|

A |

After-burn time |

Seconds |

↖20 ↖10 ↖3 ↖2 |

|

A |

After-glow time |

Seconds |

Infinity ↖120 ↖25 ↖5 |

|

B |

Contact heat |

Temp in °C after 15sec |

100° 250° 350° 500° C |

|

C |

Convective heat |

Seconds |

↖4 ↖7 ↖10 ↖18 |

|

D |

Radiant heat |

Seconds |

↖5 ↖30 ↖90 ↖150 |

|

E |

Drops of molten metal |

Number of drops |

↗5 ↗15 ↗25 ↗35 |

|

F |

Molten metal |

Gram |

30 60 120 200 |

Small Splashes Of Molten Metal (Test Method EN 348:1992)

This test is used to assess the degree of protection offered to the wearer’s hand from being struck by drops of molten metal, such as during metal grinding. In most circumstances where gloves give good results, the droplets of molten metal do not stick on the surface of the test sample but tend to run off. This significantly reduces the time in which they are in contact and does not raise the temperature of the test sample.

Large Quantities Of Molten Metal (Test Method EN ISO 9185:2007)

If testing to this clause, the use of molten iron is mandatory. However, other optional molten materials (such as aluminium or molten glass) may be tested as required and the corresponding test results must be given on the information supplied by the manufacturer.

Hopefully, this will have simplified the varying markings that are displayed but if you’re still confused don’t leave it to chance. Please contact a member of our Technical Team who will be available to advise you on the wide range of gloves we have on offer. For further information please call 0800 161 3661 or email [email protected]

Clad Safety has been operating for over 30 years and takes pride in the excellent service that we offer to our customers. Our product range, combined with expert technical knowledge allows us to offer valuable workwear and PPE solutions to a wide range of business.